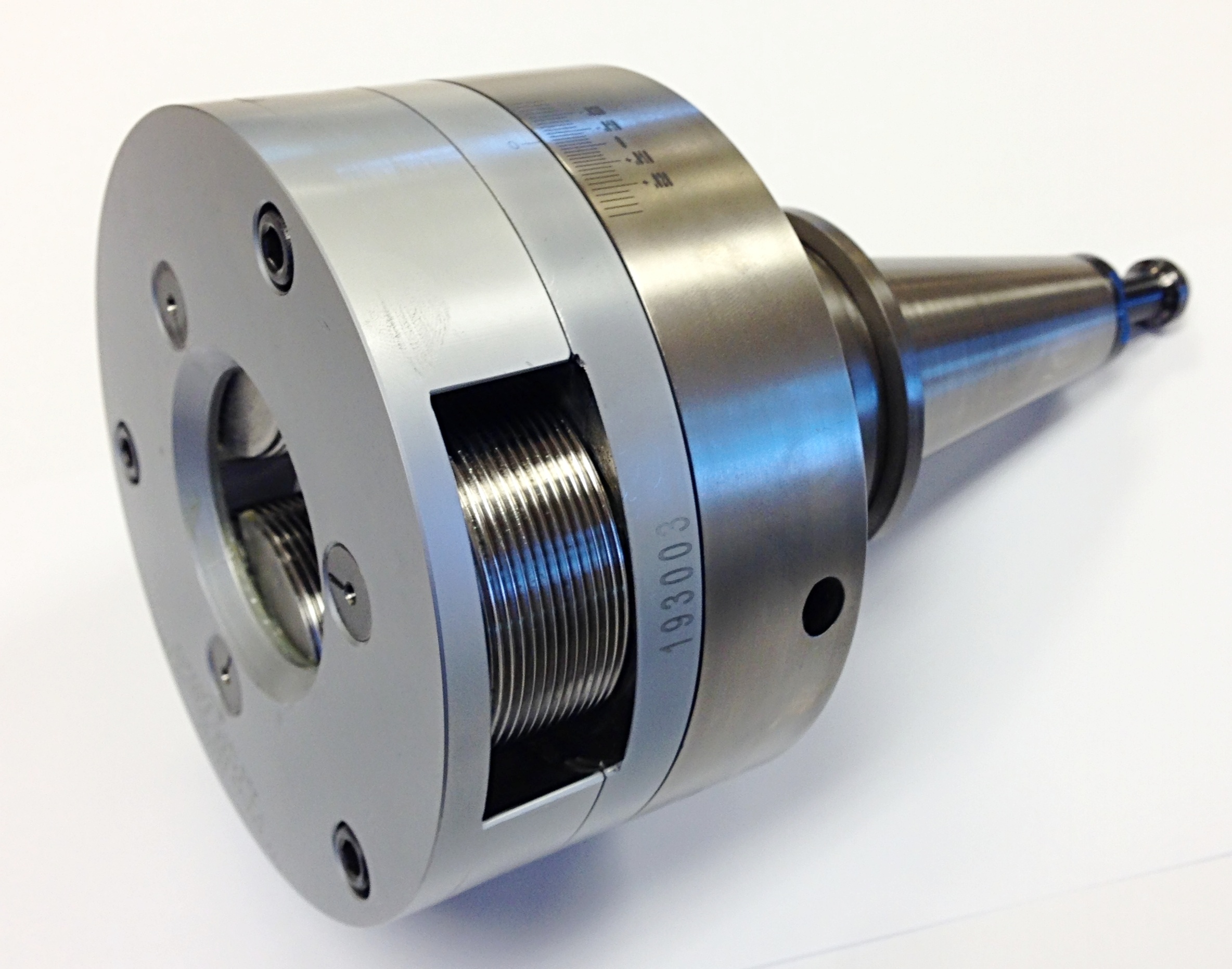

ER 193 END ROLLING ATTACHMENT

The ER 193 End Rolling Attachment features a front plate with integral standoffs that is more rigid than multi-piece assembly on the F34 head.

The clutch-less, 1-piece Cat40 shank offers increased rigidity and eliminates reset failure mode. Additional advantages include:

- Fewer wear parts than the F34 head

- Sealed pitch adjustment gear train with fine-adjust screws

- Thru-coolant capacity to lube rolls and minimize chip issues with part and rolls

- Low-friction, ultra-hard coating to increase longevity of wear components

-

193 ER style thread rolling attachment available with a Cat40 shank and 1.50 diameter shank

-

193 attachment is designed for compact rigid thread rolling on CNC lathe or mill.

-

Requires precise synchronization of rotational and feed axes of machine to maintain proper rolling geometry.

-

Uses canned threading cycle to feed on to part at proper rate as a function of part pitch – Stop – Reverse to unread off of the part.

-

Most modern CNC machines have this capability – Please verify your machine is capable of doing this.

QUESTIONS? Give us a call. Natman Corp – Toll Free: 800-345-5512

View ER 190 size specifications for both Metric ISO Threads and Unified Threads in the tables below. For all sizes, .6L, 1L and 2L are available.

Watch the ER 193 end rolling attachment at work.

Our knowledgeable and courteous sales staff is ready to assist you.

Please give us a call

Toll Free: 800-345-5512

Fax: 631-287-3638 or

Contact us by E-Mail